Gummed paper chase

If you’ve ever had cause to take a canal boat out for a spin, you might be aware of the sort of terror that only comes with the realisation that, in quite a few minutes time, you ARE going to crash and there’s absolutely nothing you can do about it. The fun thing with canal boats is that they have a top speed of very few miles per hour and boast the sort of turning circle usually reserved for glaciers. The certainty of an impact can therefore be detected quite early on, leaving the pilot with the dubious pleasure of assessing his life choices and nurture a truly exquisite form of panic in a fairly leisurely fashion as he cruises to certain doom. It also allows plenty of time for well–wishers and wags to gather along the banks to witness his inadequacies from all angles.

In September last year, this very feeling came flooding back to me. I could see trouble looming, and was helpless to divert our course. Our printer contacted me to let me know that we had only 6,000 sheets of stamp paper left in the warehouse. "No real problem" said I, "just get some more will you old bean?" The silence was prickly. Gummed paper stock, you see, is not an everyday requirement for most people and there are very few companies that produce it nowadays. Those who do tend towards a fairly modern look to their paper, with microdot glue which is almost indistinguishable to average paper. With great glee, they point out that the wonder of THEIR paper is that it looks almost entirely like normal paper.

"What about the really gloopy stuff?", I ask, "with the thick, glorious creamy surface?". Apparently, despite my views on the subject, nobody wants that any more. I try all of my usual contacts, and I’m met with the uniform response: "you don’t want that, you want this stuff, it prints beautifully, without endangering your printer and it’s got the added bonus of looking entirely like normal paper!"

September rolls on, as it has a habit of doing, and October dawns with all the charm of an unflushed lavatory. My printer does everything he possibly can to track down stock, he calls in favours, he leans on suppliers, there are even rumours of him performing strange rites late at night involving the sacrifice of ampersands.

No avail.

We scrutinise maybe twenty samples, all of which are unsuitable. Some are too flimsy, not a patch on the papers we’ve used in the past. Some won’t take an impression from a letterpress printer. Some aren’t opaque enough, leaving us with washed out colours. By the end of November, we're in dire straits. Running out of paper could prove catastrophic if you’re in the stamp printing business*. We were doing everything we could to prolong the life of the paper we had; printing fewer sheets at a time, designing sheets smaller etc. but with the next years definitives looming, disaster struck as some unnamed designer, who foolishly but very good–looking–ly, sent 3 issues to print at the wrong resolution.

Oh me, oh my — it was our busiest time of year and we had but 2,000 sheets to our name, we faced the very real prospect that we'd have to dip our quality or think of something drastic. When I tell you that we’d exhausted every avenue, I really mean it. We looked at gumming our own paper, we looked at pitching the job to other printers overseas. We talked to every paper mill and merchant in countries across the globe. We even had to consider simply varnishing the back of paper to LOOK like glue. No one, it seemed, was prepared to make the sort of paper suitable for becoming authentic postage stamps, in the sort of quantities that we required, much less someone who could do it for a price and could deliver in a month or two. Things were looking bad.

As so many of my generation before me, I prayed again to the gods of Google and finally they answered. An angel was delivered unto me. A passing mention in an old print annual referred to a Dutch merchant offering a product made by the same mill as our previous paper. What did I have to lose, this was a one in a million chance, and we all know what that means! Even if he couldn’t help, he at least knew the product we’d been used to. I dialled the number and I spoke fast. I am not sure what I said, neither did he, but something about the sobbing must have got through. I promised him a book. He promised me a sample. I promised to name my first-born son after him.

Two days later, the paper sample arrived and it was glorious. Compared to the stuff generally available, it was in another league. It was as close as a west–country cousin to the paper we’d had previously. We had to have it. I picked up the phone and dialled:

"I want it." I said.

"It’s expensive." he said.

"I don’t care." I said.

"It’s not in the country." he said.

"I don’t care." I said.

"It’ll take weeks to deliver." he said.

"I don’t care." I said.

"You’d have to buy a lot." he said.

"...how many sheets?" I said.

"How many tonnes, you mean?" he replied.

Buttocks.

The fact was, that like a badly–stocked spice rack, we were running out of thyme. We bit the bullet and ordered the minimum quantity, which the mill kindly agreed might be a little less than they usually insist upon when dealing with state–run postal systems, but which still equated to over 25 hectares of paper.

We sighed a well–deserved sigh. We pressed the button.

We buggered off for the festive period. As Christmas day dawned, our paper was to be found sailing happily across the North Sea. Towards the end of December, my printer rang to say that the paper had arrived and was in the warehouse. I was, of course, thrilled. At last we could begin printing the definitives… or so I thought. My hopes were soon to be dashed.

You see... the thing that no one ever tells you about a dense block of fake stamp paper, tightly wrapped, crossing the North Sea by boat in winter is… it bloody freezes. Nothing in my life had prepared me for such an outcome. Seldom have I had cause to thaw a sketchbook, melt a novel, or indeed incubate a post–it note.

"What do you bloody mean the bloody stamp paper is bloody frozen!?" was a phrase I never foresaw entering my life in any meaningful way. Of course, eventually, after two weeks, nature took its course. The paper thawed at a rate which didn’t cockle it, nor cause condensation (not great for sticky stamps!) and finally, when it bloody well felt like it, the paper was ready to use. Or was it...

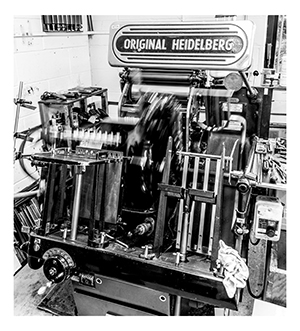

There is a small but lasting testament to the final step in our story. A little workshop in rural Somerset houses one of the finest printing presses in the south west. This very serious bit of kit is now adorned with a festive piece of Woolworths’ finest silver tinsel, circa 1984.

See... printing equipment is temperamental stuff. It doesn’t like gummed paper at the best of times and this new stuff had ever so slightly different properties to the previous batch. Before we could finally relax in the knowledge that we had the right stuff, we had to see if it would run. The day of the test arrived. Terry, our print master, cautiously threw the switch, sent the rollers into motion and held his breath as the great lumbering machine took the first few sheets into its inky depths. In this situation, you're hoping for a swish, swish, click, thunk, swish. What we got was a swish, gnrrrr, swunk, thwup. I am told this is not a good thing. The paper wasn’t feeding correctly; too many sheets were clinging together and causing a jam. For one horrifying moment we were faced with the prospect that the whole batch was useless to us. Terry stoically sighed and did what he does best, he solved the problem.

As you know, we got the paper to print in the end. The future of Discworld Stamps is safe once more. What you might not know, is that it is thanks to that small, silver scrap of tinsel, under which each and every sheet of stamps passes as it diffuses the static in the paper, allowing it to pass unheeded into the ever–open arms of ’Big Bertha’, one glorious sheet at a time.

*or in a badly stocked lavatory.

Articles

Here you will find articles mostly related to stamps, Discworld and elsewhere.

Wanted

We welcome articles from everyone, so if you feel you have something to say which will enlighted all the subscribers to the Journal please feel free to send it to the editor.

Don‘t be shy.

The Stanley Howler Journal is brought to you by the Discworld Emporium where you can find all your Flatalist needs.

August 22

January 21

Welcome the Year of the Beleaguered Badger

December 19

Year of the Condescending Carp

April 17

October 16

June 16

May 16

March 16

November 15

September 15